By Takudzwa Kufa

By Takudzwa Kufa

The Business Case for Improving Aid Processes

Large sums of aid money are frequently reported in the media as been pumped into Africa without producing the expected sustainable and transformative change in the lives of the African people. The reasons for failure of aid in Africa have been a subject of many studies and debates by various development experts with the likes of Dambisa Moyo putting forward arguments for abolishing aid altogether in her book Dead Aid. Internal inefficiencies of aid organizations and their implementing partners are some of the many indictments of aid performance in Africa often cited by critics of aid. Large non-profit organizations (NGO) and international NGO (INGOs) can have very complex systems and processes which are often the limiting factors to the efficiency of aid delivery work and the transformative effect of that aid. For example a big donor and grant making organization responds to a need such as provision of the health care facilities to a rural village in Somalia. It does this by making donation to fund recruitment of health care workers with the grant being made through an implementing UN agency known to have very complex processes and bureaucratic systems. Because of its very complex systems this UN Agency then takes thirteen months to recruit a project manager who in turn take another nine months to get approval to recruit the health workers needed on the ground. So for close to two years, the resources were available, but the people’s lives were not being transformed due to lack of operational and organizational effectiveness of implementing organization. Such inefficiencies and waste has been the story of aid in Africa whose delivery is very slow, wasteful and short-changing to both the donor and beneficiary community.

In these times of austerity, with the economies of major donor nations in recession or slowdown, there is increasing pressure from their public to cut aid budgets. Calls for greater scrutiny on how the tax payers contribution to international development aid is spend are now making frequent headlines in the developed world media. According to The Guardian 16/11/2012, whilst Britain has committed itself to meet the UN target of spending 0.7% of gross national income on development assistance, its coalition government is increasing coming under strong pressure from the conservative party back benchers to reduce foreign aid spending at a time of deep budget cuts at home. The Taxpayers ‘Alliance, Britain’s independent grassroots campaigner for lower taxes published a report titled Lost Along the Way putting an argument that the current way in which UK aid is delivered by the Department for International Development (DfID) does not give value for the UK Taxpayer. They raised objections to international call for increasing aid without taking considerations to public concerns about aid effectiveness. The report attempts to calculates how much of each UK taxpayer’s pound given to international development through DfID ultimately gets to the intended recipients, It goes further to estimate how much DfID cooperation with intermediary organizations (such as the UN, EU or Oxfam) costs the UK taxpayer. It questions the efficiency of DFID and its development partners who include well known INGOs and Civil Society Organizations (CSO). This report noted three interesting observations:

1) For every pound given by the taxpayer towards international development and humanitarian assistance, 5 pence is lost in the administration of DfID itself.

2) For every pound given by the taxpayer (towards international development and humanitarian assistance) and then spent by DfID through multilateral organizations, 5 pence is lost in the administration of DfID itself. Of the remaining 95 pence, approximately 15 pence (on average) is lost in the administration of the multilateral organizations.

3) For every pound given by the taxpayer (towards international development and humanitarian assistance) and then spent by DfID through INGOs/CSOs, 5 pence is lost in the administration of DfID itself. Of the remaining 95 pence, approximately 19 pence (on average) is lost in their administrative and other non-front line functions.

The report concluded that

“International structures and organizations represent a highly bureaucratic approach to development; one that will consume an even greater share of the UK’s overseas assistance as spending grows. New and radical development strategies must be deployed, for as progress in the developing world falters, people would be right to question whether the current approach is delivering the best value for money.”

Alongside other topics of transparency and accountability the debate on improving aid effectiveness has been played on international arena as well. The Paris Declaration on Aid Effectiveness (2005) and Accra Agenda for Action (2008) saw the Heads of multilateral and bilateral institutions resolving to take far reaching and monitorable actions to reform the management and delivery of aid as they looked ahead towards UN first 5 year review of the millennium development goals (MDGs). They recognised the need to increase the volume of aid and to increase its effectiveness whilst reaffirming their commitments to the High-Level Forum on Harmonization in Rome (February 2003). They resolved to (1) scale up for more effective aid (2) adapt and apply to differing country situation (3) specify indicators, timetables and targets, (4) monitor and evaluate implementation in addition to establishing partnership commitments on principles ownership, harmonization, alignment, managing for results and mutual accountability of aid.

From the above paragraphs, it is clear that this agenda for increasing aid effectiveness set locally and coordinated at international level has far reaching implications for organizational and operational strategy for the whole aid industry. This international drive to improve aid delivery, management for maximum positive impact, poverty reduction, achieving MDG goals and value for money has set in motion various strategic improvement initiatives by international development aid agencies (AusAID, DfID), their partners who include receiving governments, multilateral institutions (IMF, World Bank), bilateral, international NGO and Recipient Societies Organizations.

The Australian Government (AusAid) goal is to become the “world leader in aid effectiveness” as stated in their new aid policy document “An effective Aid for Australia Making Real Deference- Delivering Results” published 2011. The supporting framework document” The Australia Comprehensive Aid Policy Framework 2015-16″ published 2012 goes further to set (1) an agenda for managing aid for improved results and performance (2) establishes a performance framework for reporting results, a framework placing emphasis on operational and organizational effectiveness. Concerns about poor aid effectiveness are shared by charitable and philanthropic grant making organizations as well. Tamary Diaz Otero on her Blog Effectiveness of Aid: How to Improve with Diminishing Resources 28/12/2011 quotes results of a survey by Devex partnered by McKinskey & Co which reported that only 35% of NGO participants to High level Forum on Aid Effectiveness HLF – 4 in Busani thought that projects they manage achieve intended purpose.

These debates on aid effectiveness brings to the fore the strategic and business case for improving the whole processes of aid management. The quality of aid delivery is failing partly because of poor performing organizational processes performed by actors in the aid industry. A strong argument can be made that processes in this industry are not managed and aligned to deliver appropriate outcomes efficiently. Without changes in processes the narrative of Aid in Africa will continue to be stories of vaccines taking two months to be delivered to a community reaching recipients well after the outbreak has killed many people, a story of administrative costs as high as 50 cents for every dollar spend, the largest fleet of 4×4 SUV Toyota Land Cruiser utility vehicles, latest model of laptops and mobile phones.

Calls for the NGOs to deliver noble cause efficiently and calls to take lessons from other industries are becoming louder as development policy makers, academics and practitioners recognize the need to apply better management science to challenges of global poverty ( management4development, 2012). In a recent presentation at Ted Talks, Melinda Gates of the Bill & Melinda Gates Foundation challenged NGOs to take lessons from corporations like The Coca-Cola Company who manage to deliver a coca cola to the most remote part of the world efficiently. She questions why NGO involved in provision of condoms, sanitation and vaccinations fail to do the same. She identified that Coca Cola works with real-time data, it is capable of responding immediately to market demands, it taps into local entrepreneurial talent and it has a global network of marketers and distributors who ensures that every remote village can demand and get a coca cola (m4d, 2012). What she failed to identify is that at the heart of this efficiency is a culture of process excellence and total quality management (TQM) principles guiding the company’s operations management. Efficient operations management at Coca Cola are guided by Lean Six Sigma (The Coca Cola Business Process Excellence Program) and Total Quality Management (TQM) principles contained within The Coca-Cola Quality System (TCCQS).

Lean Six Sigma is an improvement tool whose origins is part car manufacturing and part telecommunication industry i.e Toyota Production System and Motorola. At the heart of this tool is the systems thinking and process approach to management therefore potentially capable of being used in any organisation. INGOs and whole aid industry in Africa can benefit from this tool if properly implemented. Ironically Toyota produces the very reliable and NGO preferred motor vehicle used in aid operations Africa, the Toyota Land Cruiser. Some international NGOs like World Vision International have rightly identified that the impact and effectiveness of their work is closely related to performance of their internal organisational processes. They have looked outside their own industry for process improvement tools. World Vision embarked on a Lean Six Sigma program in their East Africa Region, World Vision Process Excellence (Parris 2012)

TQM is a way of thinking about the whole organisation, goals, structure, products, processes and people, that aims making the right things to be done right first time (CQI, 2012). This thought process can change attitudes, behaviour to ensure better outcomes. In an INGO this thinking will mean activities are done right first time. Rather than relying on monitoring and evaluation (quality control) at the end of the projects, quality of outcomes is built and assured at every stage of the process and that systems are geared towards quality of project and meeting stakeholder expectations.

Whilst Coca Cola is a multi national corporation (MNC) motivated by profit to achieve processes excellence, efficiency, waste reduction and fast response times to customer demand, INGOs and Aid organisations especially those involved in humanitarian and relief work are now facing the same pressure to respond quickly to stakeholder demands and to produce bigger impact for less despite being none profit driven. According to Parris 2012, in spite of their unique challenges,INGOs have support functions such as Human Resources, Finance, Supply Chain and IT that are similar to MNCs. The challenge for the NGO industry in Africa is to look outside for suitable tools that can deliver the required process improvement and cultural change.

Lean Six Sigma: Lessons from the Food Industry

In these times of global economic slowdown the UK food industry continue to experience significant pressures on manufacturing margins which makes operational efficiency crucial to its profitability. Consequently in recent years lean manufacturing and Six Sigma have become buzzwords in the food industry as manufactures look up to both methods for improving operational efficiency, creating new organisational structures, process excellence, continuous improvement and a lean culture. Likewise NGOs are faced with limited resources in these times of global austerity and coupled with the increasing pressure in donor countries for reduction of aid, operational efficiency has become key factor to successful outcomes of NGO projects and programs. Aid organisations can also benefit from proven improvement tools such as Lean Six Sigma (DMAIC) also referred to as Lean Six Sigma. The NGO sector can learn from the food industry efforts at improving operational efficiency and transformation to new organisational cultures of customer focus (stakeholder), process excellence and continuous improvement using Lean Six Sigma.

As highlighted earlier Lean Six Sigma (DMAIC) is a combination of two methodologies. At the heart of both methods is the system thinking and process approach to management.

Lean is a method for achieving continuous improvement (kaizen) in organisational performance through elimination of waste from the total organisational process, but it cannot continually deliver improved process capability and stability. On the other hand Six Sigma is a structured approach for reducing product and process variability (stability) and increasing process capability but does not always bring improvements in process flow, speed and flexibility, hence the need for combining the two. So for the Lean Six Sigma to work, the supporting organisational structures should be designed to facilitate uninterrupted flow of the core work process, focusing on eliminating waste and maximising customer value.

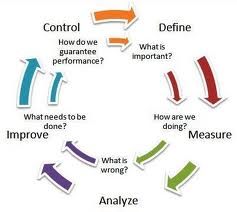

DMAIC is an abbreviation for Define, Measure, Analyse, Improve and Control. It is a five step pathway providing a common structure for integrating Lean and Six Sigma methods. The DMAIC improvement cycle is the core process used to drive Six Sigma projects. All of the DMAIC process steps are required and always proceed in this order. DMAIC is not exclusive to Six Sigma; it can be used as the framework for other improvement applications. It is a data-driven improvement cycle used for improving, optimizing and stabilizing business processes and designs. NGO and Aid organisations can benefit from it too by using it as a guide to answer questions about their performance, solve problems and drive improvement.

NGO processes shares in principle similarities with some food manufacturing processes which makes the food industry a good candidate for the NGO/ Aid industry to assess and benchmark for leading practice outside (some call it best practice) . Unlike the car manufacturing where Lean Six Sigma originates from, the standards of process outputs “What good looks like” in both industries are not always defined in absolute objective figures that are too narrow specifications e.g. 2 mm. “What good looks like” can be a range of acceptable subjective colours and flavours, or some objective stakeholder/customer satisfaction measure. Consumer judgments of a good product are rooted in emotions, sensory and cultural perceptions. The judgement of good aid outcome is not a straight measurement. The NGOs industry in Africa share another similarity with UK Food manufacturing. They have a common “waste stream” i.e. “the waste of talent and skill” The UK food industry attracts a highly qualified migrant labour force made of doctors, lawyers and engineers and graduates from east Europe and Non EU migrants to do menial packing operations because of better wage compared to their countries of origins. This class of workers have been reported to have better work ethics than local labour and have be credited for delivering huge efficiency for the food manufactures. But with limited opportunities for career progression and low social mobility for ethnic minorities in England this labour force is prone to run out of steam and motivation with huge implications quality of output. The NGO sector in Africa employees the largest number of Ph.Ds, master’s and undergraduate degree holders. It has a layer of so many experts doing work that can easily be done with none graduates. This over concentration of skills creates bloated administration costs; creates bureaucracy, over processing of work, unnecessary process gates, loss of motivation, a disproportionate focus on research aspects of projects and too much report writing. In addition to others, this similarity in the character of outputs and a common process waste stream makes a compelling case for NGO management to benchmark processes with food manufacturing.

Challenges for Process Improvement In Africa

Aid delivering organisations (NGOs) work with various local partners who makes the challenge to driving process improvement a much bigger than just taking consideration of their internal organisational processess. External stakeholders, partners, environmental and cultural contexts must be taken into consideration. So the pace of effectiving change depends on other organisations and supporting business environment.

Africa has its unique set of socio economic challenges that shape organisational behaviour and with implications for process excellence on the continent. African organisations especially NGOs are managed by arguably some of the most educated citizen of the continent but somehow they have structural, organisational, economic, social and culture specific characteristics that make processes slow, output low and waste high. There are limited jobs or economic opportunities in Africa and in many organisations those who don’t agree with change cannot just walk away or resign. The natural instinctive reaction to change is self-preservation and change has to preserve people’s jobs and economic interest. Decisions that involved change are considered carefully taking into account what’s in it for me and my family or constituency. In typical african organisation proposals about change are debated over and over again in very inclusive and bureaucratic fashion. Decision making in African culture often aims at reaching consensus and maintaining good relations as an overriding objective (Khoza, 2006). But development of this prized consensus can be subjected to some sort of bargaining arrangements, consequently making the resulting change outcome not the most economically efficient but just the most face and relationship saving. These economic and cultural factors among others slow down the pace of change in Africa and NGOs should learn to navigate this terrain in a smarter way to achieve faster organisational changes prerequisite to process improvement.

Job security and remuneration concerns in Africa seldom provide economic incentives to slow down organisational processes. For example computerization was resisted for the greater part of the 1980s and 90s in Zimbabwean private and public organisations because of concerns that extra process efficiency would cause work redundancies. Business leaders under the pressure of workers unions and personal interest avoided computerisation in favour of manual inefficient systems. This partly explains the lower level of ICT literacy and use in both public and private sectors in Zimbabwe compared to other countries such Rwanda and Kenya. So in Africa sometimes there are economic interests to make systems and processes slow and worse if slow systems present opportunities for economic rent seeking, processes are designed and managed to be slow even starting at strategic levels. African countries have probably some of the most staffed civil service sectors compared to private sectors yet poor service is the norm, accepted and expected. Processes in civil service sectors are made slow and inconveniencing so that people are incentivised to give bribes to rent seeking officials if they want faster services. Absence of strong leadership will, management commitment, suitable performance matrices, visible KPIs and data driven structured problem solving (tools Lean Six Sigma can bring) shields these problems from being solved right from their root causes. NGOs in Africa interface with these organisations as partners, service providers and regulators with huge implications for their own efficiency. In the NGOs sector where per diem rates are paid for attending meetings and conferences, there are economic interests for organizing travels, training, meeting, drawn out project schedules and unnecessary visits, all which contribute to slow delivery, inefficient and ineffective outcomes.

NGOs in Africa provide the prized jobs which normally pay in dollars or higher salaries in countries where an average employee has more than his or her family to feed. In African countries amidst low employment levels, absent social security and low safety nets for the poor and unemployed, those employed are expected to look after an extended family of siblings, in-laws, cousins and parents. Finding employment with an NGO comes with higher salaries but even higher extended family and community expectations for help with medical, school fees for their kids or even use of 4X4 vehicle for family and community funerals etc. People have so many distractions of phone calls or even visits from grandmothers or uncles from the village who can even turn up at work to ask for money. This societal pressure distracts some NGO employees from efficient working.

As an African migrant worker in the UK food industry, I draw upon my experiences and observations working in the food manufacturing in a quality assurance function and my project management and development work in donor funded projects in Africa to argue a case for the use of Lean Six Sigma in delivery of aid in Africa. Its impact is more than profit and savings but leads to more saved lives and improved livelihoods. Creative Lean Six Sigma process improvement programs can deliver significant gains if their deployment strategy & process, educational support, training support, systems support and change management processes are managed correctly addressing the unique local cultural organizational contexts. In the food industry we use Lean Six Sigma (DMAIC) is to create brilliant processes which add value, minimize waste, which are capable, available (when required), with flow and flexibility. I see a huge opportunity and role for use of Lean Six Sigma in improving aid effectiveness in Africa. It can be applied creatively under the drive of stakeholder’s requirements “voice of the customer” to provide powerful tools that drives out process waste, improve process speed in the non-profit sector (NGO) most importantly drive out the culture of waste that defines the industry today. Organisational improvement practitioners in the NGOs and aid industry in Africa must draw upon Lean Six Sigma to proactively direct organisations, solve problems, continuously improve processes and achieve organisational effectiveness.

Lean Six Sigma: Creating Excellent Processes for Better Outcomes

The lean methodology is based on the Toyota Production Systems (TPS); whose three key features are 1) Cost reduction through waste elimination and increase flow 2) Continuous improvement (kaizen) of processes and 3) Employee involvement. These concepts when exported from manufacturing to the non-profit sector they can create NGOs with brilliant processes which are efficient at reducing waste and maximizing flow. Efficient processes in the context of NGOs are processes that are simple, visually organised with clear work flows, mapped value streams, standardized and integrated with clear responsibilities and scope, defined roles, policies, and outcome objectives.

Just as in TPS where processes that are empowering to the employees are promoted, a lean NGOs needs to have processes empowering to stakeholders. This means processes in a lean NGO ensure decisions are made locally, stakeholders participate in processes and the processes are geared towards capacity building. Participatory approaches including team work are part of the organisation’s processes. Just like in TPS, processes of a lean NGO must be continuously improving. For processes to be continually improving they need to be performance monitored, measured and corrective and preventative actions taken to address root causes of failures. The focus is on improving the quality of organisational processes which in turn actually reduces cost more than the focus on cost itself according to the “The Toyota Way”.

The phrase Six Sigma in a manufacturing organization would refer to a measure of quality that strives for near perfection i.e. less than 3.4 defects per million opportunities (outputs). Six Sigma the tool, seeks to improve the quality of process outputs by identifying and removing the causes of defects (errors) and minimizing variability in manufacturing and business processes. Developed at Motorola in the 1986, Six Sigma is complementary to lean. It uses a collection quality management and statistical tools to gives a rigorous structured methodology for reducing product and process variability. It has strong focus on critical to quality customer (CTQ) requirements. It requires rigorous analysis of data to resolve problems. It is concerned with identifying sources of variations; designing, setting and managing of process performance, complexity, capability and reliability. It takes a project based approach to continuous improvement. It is about identifying and quantifying key sources of variations, eliminating and controlling them. Pande, Neuman & Cavanagh, 2003 in their book The Six Sigma Way summarized six key critical ingredients required for an organisation to achieve six sigma capabilities,

- Genuine focus on customer ( Genuine stakeholder focus)

- Data & Fact Driven Management

- Process Focus, Management & Improvement

- Proactive Management

- Boundaryless Collaboration

- Drive for perfection

Applying of Six Sigma tools to NGOs will go a long way towards improving the quality of outcomes since knowledge of stakeholder requirements and effective data driven measurements (DMAIC) mandates them to consider 3 important actions about their processes (1) process improvement (2) process design/redesign and (3) process management. Processes that are critical to stakeholders (CTS) requirements must be designed/redesigned, improved and managed to be effective. Effective processes are simple, reliable, delivering measurable and transformative results. They produce high quality outputs or outcomes in a timely manner. The second implication of applying Six Sigma to an NGO process environment is that processes are made appropriate to the objectives of the organisation. Appropriate processes are those processes with the capability of delivering transformative outcomes with minimum variation (consistency). They are a result of good stakeholder engagement process; they are designed for the stakeholder and flexible enough to adapt to change. To achieve this required capability, suitable technological innovations and solutions must be applied to processes when possible. Typical technological solutions that can improve the capability of NGO processes include those which bring about automation, computerization real time data monitoring, analysis and reporting e.g. a mobile phone communication and productivity device/application (mobile apps) . For example if there was a mobile phone application that exist and is available for use by village nurses in Malawi to report daily logs of HIV anti-retroviral drugs collected by HIV patients at their rural village clinic. This mobile app would allow an NGO providing anti-retroviral drugs to keep abreast with real-time data for performance monitoring and evaluation, better management of stocks, better supply chain coordination, less time wasted visiting the project, faster response times and timely problem solving. These technical solutions must be fit for purpose with the user environments and project conditions taken into consideration.

In summary non-profit organizations can do much more with fewer resources to transform more lives by using this integrated approach (Lean Six Sigma) which creates brilliant processes which are appropriate, effective, efficient, empowering and continuously improving , the AEEEC Processes’

Andrew Parris at World Vision East Africa Regional Office championed the use of Lean Six Sigma in the NGO sector in 2010 by developing the best framework for implementing brilliant processes in a not for profit organization “Process Excellence in World Vision”. He identified the similar process attributes above which I have given an acronym AEEEC. These process attributes have guided the implementation of World Vision Process Excellence Program and have already been reported as having increased process speeds by factors of 40-80 percent in recruitment and procurement processes. World Vision has found that implementing Lean-6-Sigma does not only make works more productive but makes it more enjoyable to staff.

Six Sigma within an NGO environment goes further than just describing excellent process attributes. It can be used to improve project/programme planning, monitoring and evaluation in addition to implementation process. Its DMAIC pathway is evaluative hence it can be used together with the program logic models to understand the rational behind project intervention and to justify with numerical facts and data modifications to the logical frameworks. Six Sigma can play the role of a framework for managing community projects, adding value to stakeholder analysis processes by providing a framework for learning, planning and evaluation of community needs. It can be used as a strategic directing tool aligning organisational strategy to processes measures KPI and providing technical solutions. Implementing Six Sigma in NGO will involve changing culture, a new process management approach that focus aims at managing processes in a systematic way across functions and breaking silos and aligning functions.

Applying Lean Six Sigma to NGOs: The Deployment Strategy

Embarking on a continuous improvement program is like setting on journey to a destination called “Excellence”. This journey to “Excellence” involves the whole organization working together creating brilliant processes. The organization has already appreciated the importance of internal organisational processes in achieving successful development outcomes. They now know that they needs to change from one place to another by embarking on this journey, solving problems, improving processes and finding excellence along the way. Such a journey plan naturally raises a few questions about when to start, where to start from, how to make it happen and how to identify arrival at the preferred destination “Excellent”? I will answer the questions later.

Lean Six Sigma is one of the preferred vehicles to take an organization to destination “Excellent” A licensed driver and trained crew

(project teams) who are capable to steering the bus through various stages of the DMAIC road that lead to “Excellence” are required. The crew must be well trained, committed and motivated to facilitate a pleasant journey whilst ready to answer questions that arise along the way.

Improvement practitioners within organisations are the drivers who use Lean Six Sigma tools to proactively solve problems in a structured way, design/ redesign and improve processes within sponsored projects. The challenge for many organisations is sustaining the gains from and from these projects. These sponsored projects are implemented through project team structures whose organization, roles and responsibilities must be clearly defined and aligned